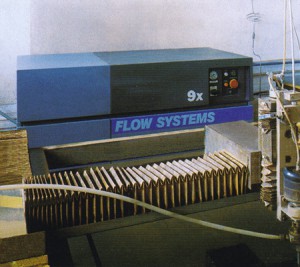

The material division in Bravo Loštice Ltd. is realized at the shape material-division workstation by means of the high-pressure water and hydro-abrasive beam.

The system is based on the high-pressure pump equipped with several multiplicators which generates a water pressure up to 400 MPa (4 000 Bar). High-pressure pipe then transport under this pressure the water to the cutting head which accomplish the shape material-division.

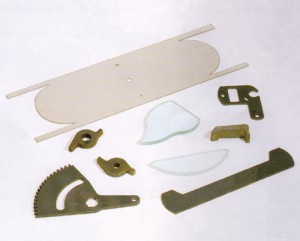

Result of hydro-abrasive beam shape material-division The movement of the cutting head is controlled by the CNC system, which makes possible arbitrary shape cutting with a high precision and unlimited number of precise re-runs.

What could be cutted by the water or hydro-abrasive beam?

Arbitrary shapes including drilling and cutting holes and shaped cutouts with the option of masaic-type nesting of different materials. The sharp edges are kept even in the case of cutting a very soft material e.g. expanded polystyrene, foam rubber, leather etc., the quality of the cut (the roughness of the surface) could be set from a rough cut to a perfectly smooth one. The input is possible in the electronic form on the floppy disc (AutoCad, formates *.dwg, *.dfx), in the engeneering drawing form or working drawing one.

Size of the cutting table – 2000 x 3000 mm

Thickness of the cutted material – up to 150 mm

Possible materials for material division:

- all types of steel, metal and their alloys

- all types of plastic materials and rubbers including foam rubber

- caramics and pottery including the glazed products

- natural and arteficial stone including the gemstones for noble artwork

- wood, chipboard, plywood, veneered materials and cork

- arbitrary textile materials including the carpets and felt

- leather and imitation leather

- arbitrary layered (sandwich) materials even when soft and hard layers are alternating

- constructional materials and revetment based on cement, gypsum or synthetic materials

- arbitrary composite materials – BRIEFLY ANYTHING!

Summary of this technology adventages:

- cool and very precise cut with the max. offset 0.2 mm

- the edges and the cut-surfaces with no need for the post-treatment

- low costs of piece-work and short-run orders

- the possibility of a mosaic-output and marquetry (even from totaly different materials)

- the possibility of an arbitrary material division (including layered and compound ones)

- the cut with no microcracks, microgrips, setting or other subsequent thermal, chemical or mechanical disruption of the cut surroundings

- drilling and cutting with single tool with no interaction between the tool and material

- unlimited number of shape cuts, outcuts up to very fine pieces

- the possibility of division of surface-finished materials (polished, coloured, electroplated etc.) with no scratching or finishing damages

- during the division there are no chemical reactions, do not originate any environmentally unfriendly fluids or gases and no chemical changes of material are done.